“Creativity, 40 percent oil shale ash and 100% good vibes”

Imagine: one day early in the morning you arrive at an empty field, no buildings, apartments or any sort of existing construction. You go past, uninterested, however happen to return 20 hours later in the evening, and get to see an already fully constructed houSse, ready to meet its residents. This is not a merely futuristic scenario, in fact the technology capable of doing that has existed since 1939! Meet concrete 3D printing. So what is it?

What is 3D printing?

3D printing, or additive manufacturing, is a modern method of designing physical objects via building them layer by layer with a digital 3D model. Unlike traditional manufacturing, which removes material through cutting or milling, 3D printing adds material only where required, causing massive reduction of waste and enabling highly complex structures.

How does the 3D printing process work?

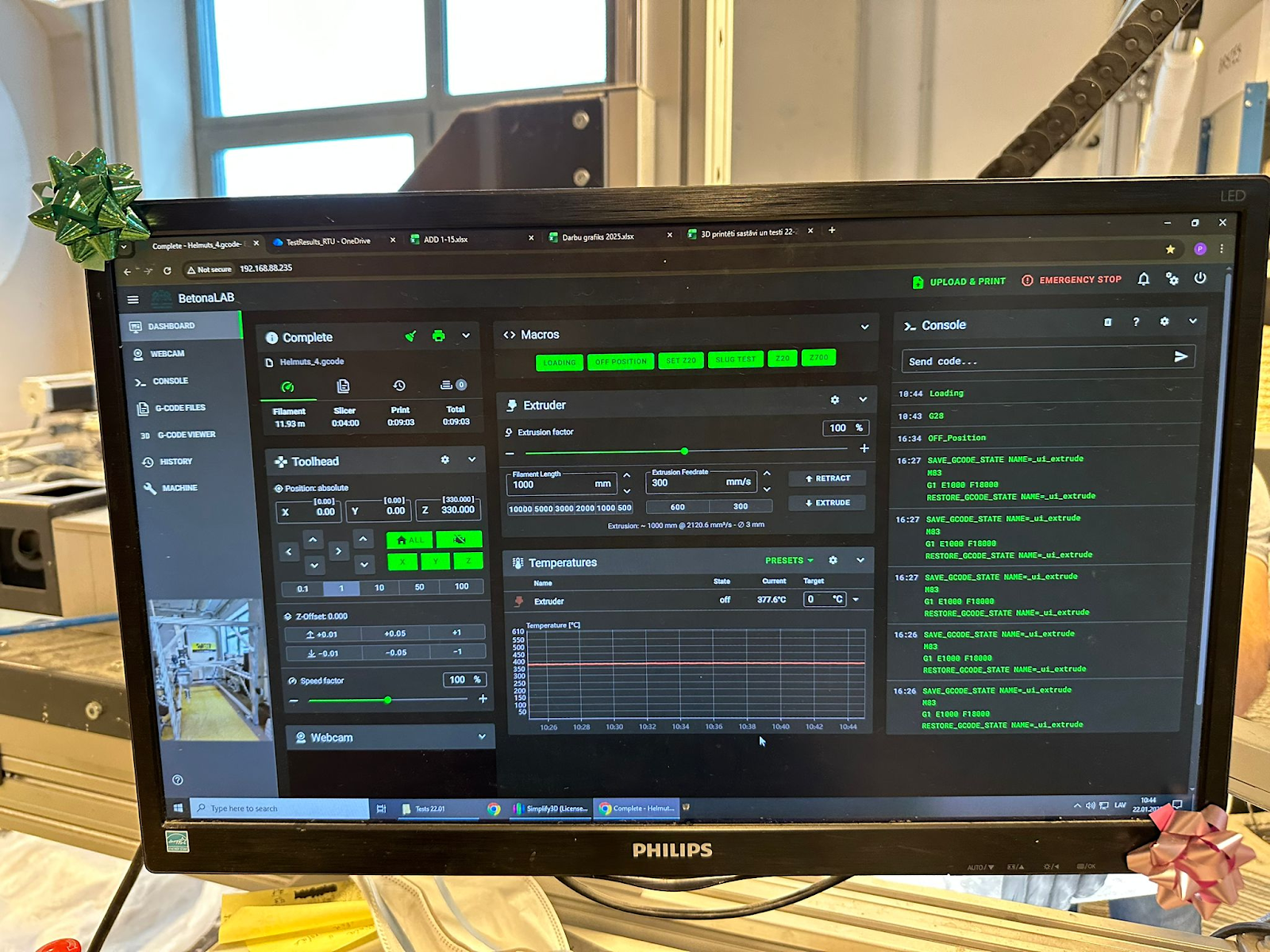

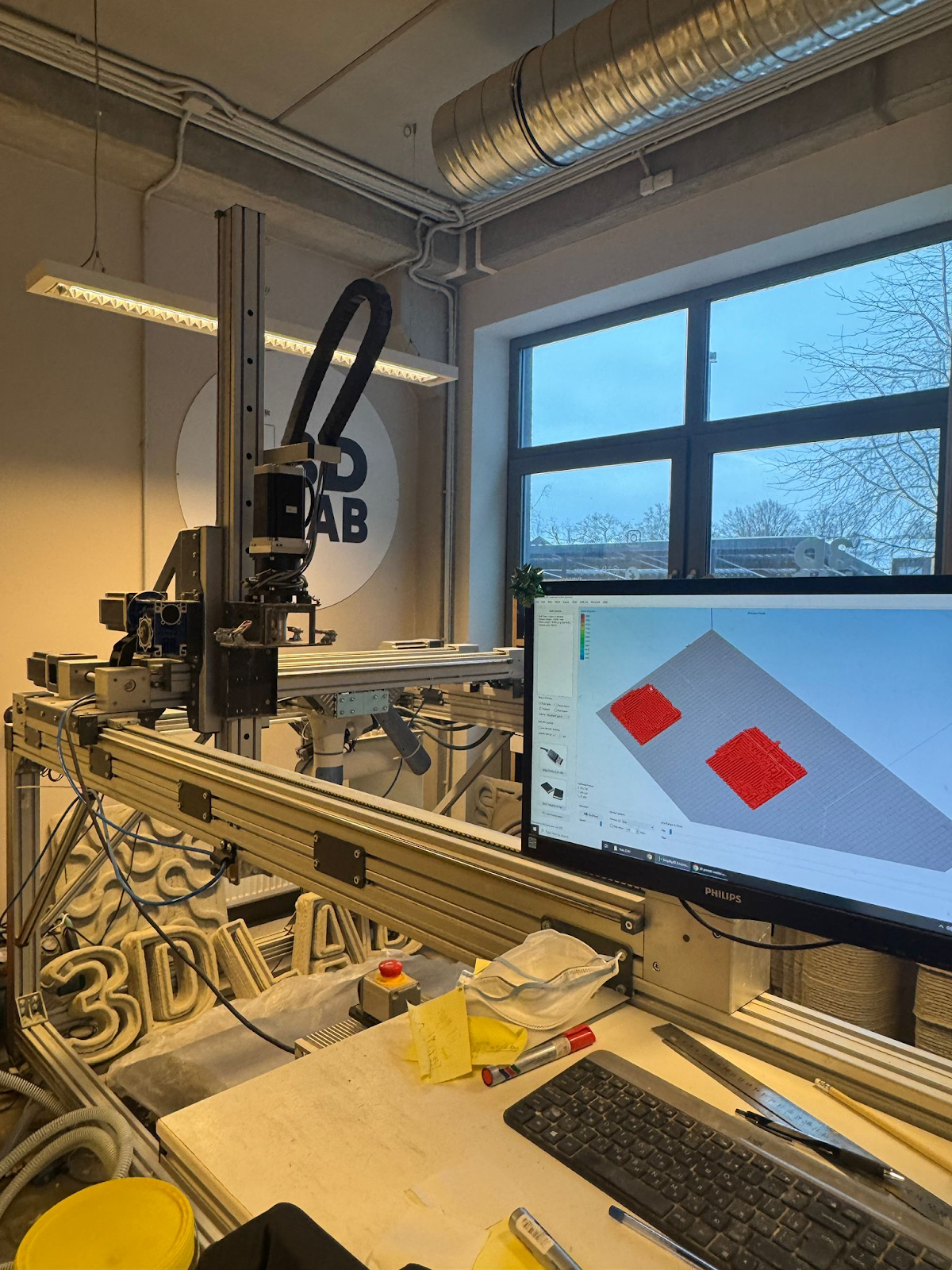

The process begins with a digital model created in CAD software (Computer-aided design) or obtained via 3D scanning. This model is sliced into thin layers using specialized applications, which generate instructions for the printer to abide by. The printer then proceeds to form the objects layer by layer by extruding melted plastic, curing liquid resin with light, or fusing powdered material using a laser or electron beam. After printing, post-processing such as cleaning, curing, or polishing is often needed.

What materials are used in 3D printing?

Common materials include plastics like PLA, ABS, PETG, and nylon, which are widely used for prototyping and consumer products. Resin materials are utilized when high detail is required, especially in dentistry and jewelry. Metals such as stainless steel, aluminum, and titanium are used in industrial, medical, and aerospace applications. Other materials include fiber-reinforced composites, ceramics, concrete, and experimental bio-materials.

Where and how is 3D printing used?

3D printing is globally used for rapid prototyping, allowing fast testing and refinement of designs. It is also applied in manufacturing for custom or low-volume parts, in medicine for prosthetics, implants, and surgical tools, and in education through desktop printers.

What is the status of 3D printing in the modern world?

Today, 3D printing is a mature and widely adopted technology, but it does not fully replace mass production. It is most effective in situations that demand customization, design complexity, or rapid development. As a result, it functions as a complementary technology within modern manufacturing rather than a universal solution.

3D Printing at RTU Laboratories

RTU laboratories are equipped with modern 3D printers that work with different materials, such as plastics, resins, and composites. These laboratories are used by students from engineering, design, robotics, and architecture programmes. The technology allows them to test and develop ideas without expensive traditional manufacturing.

Researchers at RTU also use 3D printing to produce innovative solutions in areas like medical devices, smart materials, and sustainable engineering.

The life of the Lab

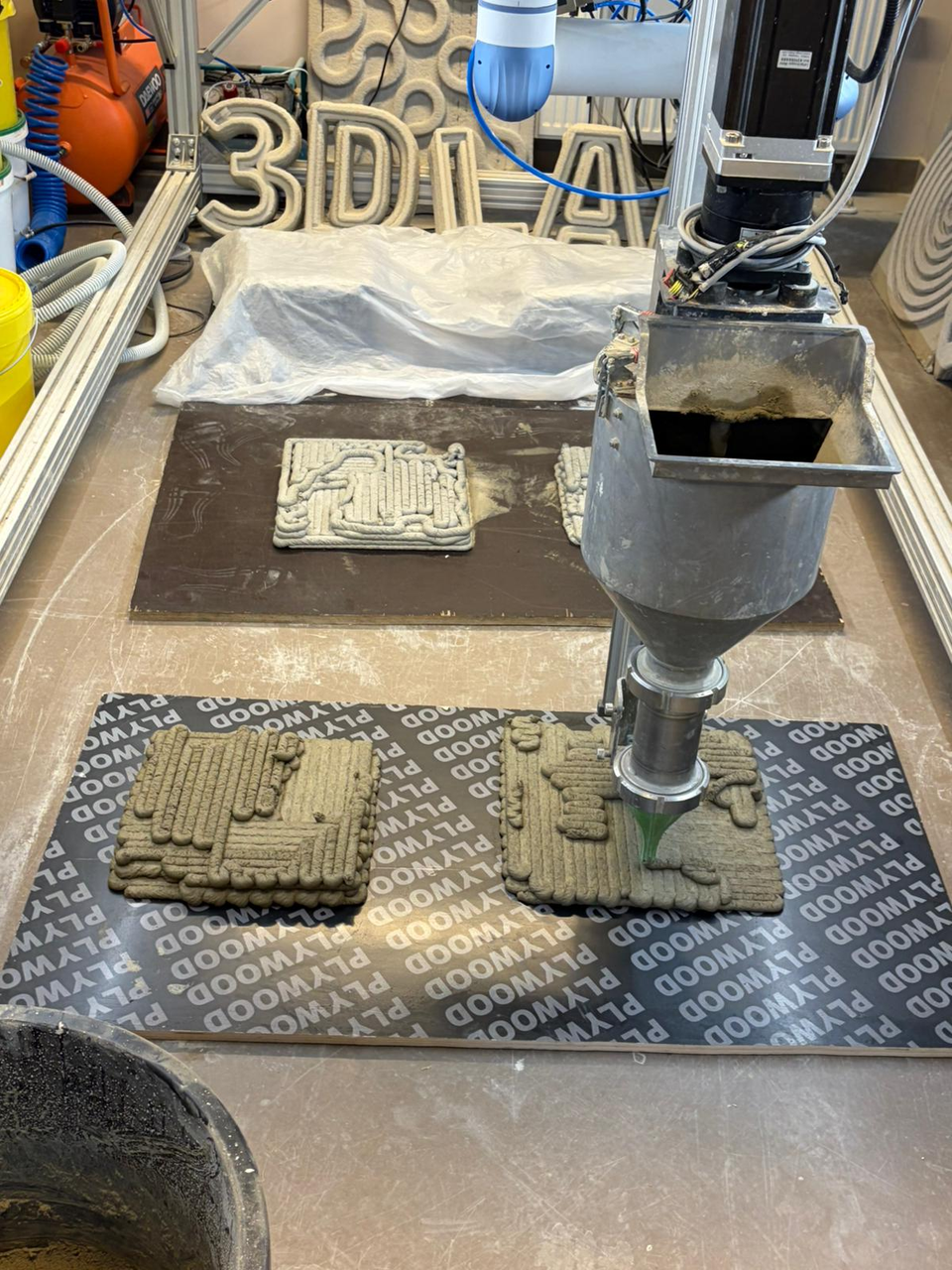

Today we explored RTU’s 3d concrete printing laboratory and we will share our findings about this truly unique place. The laboratory was first established in 2021 by its current leader Māris Šinka, senior researcher at the Institute of Sustainable Building Materials and Engineering Systems at Riga Technical University (RTU). Driven by his enthusiasm for sustainable technology, he founded such a facility in the Baltic region in collaboration with building materials manufacturer SAKRET, to research materials and their potential in industrial 3D printing.

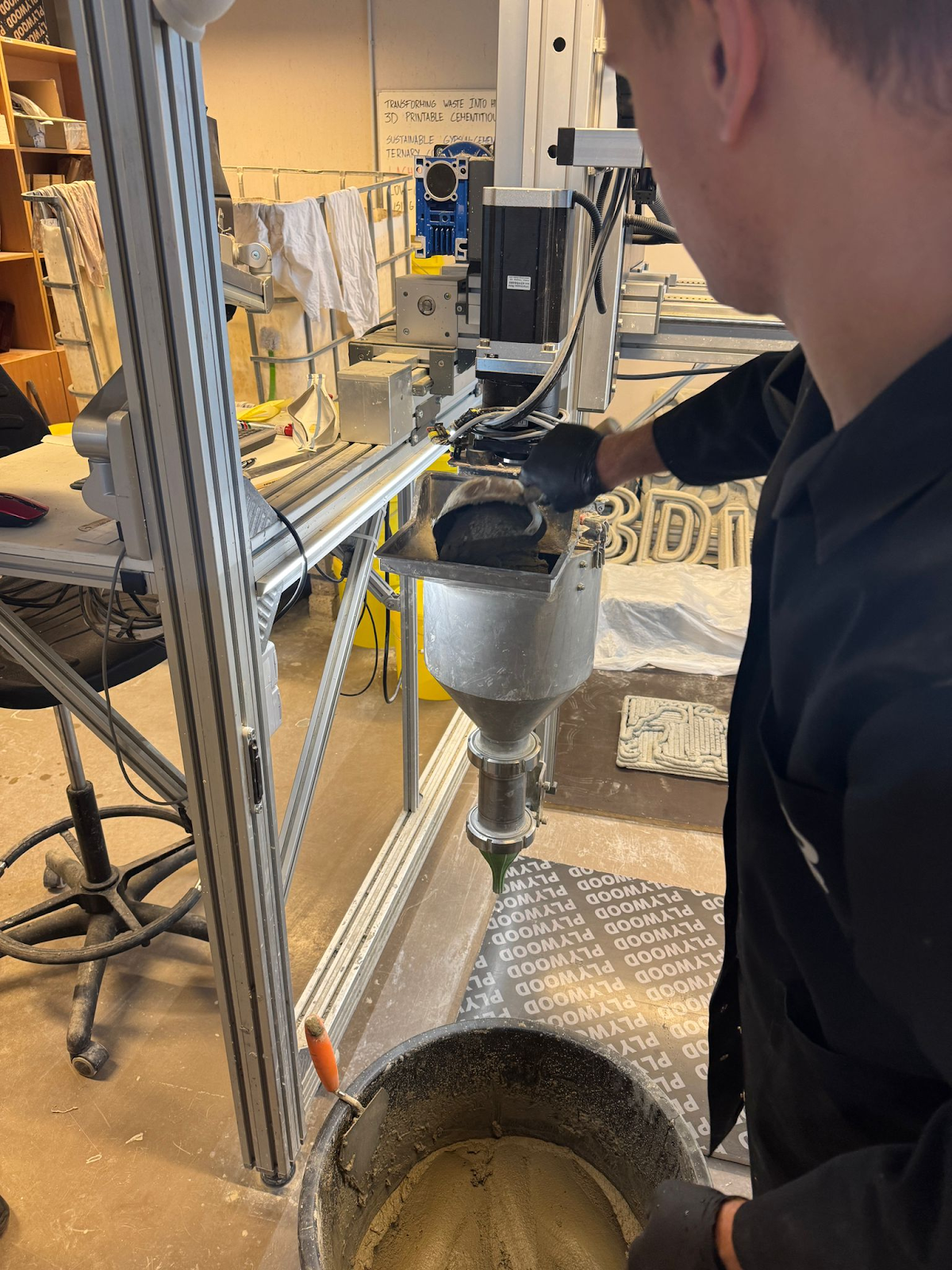

Currently there are 5 people regularly operating the laboratory and doing research. One of them, RTU Ph.D. student Dāvis Dragons, walked us through the lab and showed us everything that there is. The lab has 2 main areas of activity. The first one is material preparation and testing, and the second one is, of course, printing itself.

In the material testing, they twist, freeze in chambers and crush concrete with different machines, to discover bounds of its applicability. For example the left picture shows a 300 ton press, used to test compressive strength of the concrete and on the right, there is a “fridge” (freezing chamber) to test concrete under different temperature conditions and find out its thermal properties.

Among the various machines used in the lab, some may appear quite old. For example, the debris crusher, used to recycle construction debris into usable concrete, is 2 decades old, which highlights a rich history of the place. This occasionally creates trouble for the people operating with them. As Dāvis himself mentioned, “Wrong move can easily cause an oil leak”.

But the work of the laboratory spread beyond its walls. Right outside of the building, there is him, the symbol of innovation, LabLab. 2 ton 3D printed concrete statue is the highest and the largest object produced in the lab. It also is part of life of the lab and the whole RTU community. On December 10th the whole RTU celebrated its 2nd birthday.

To this day the lab actively develops engaging new, young students from RTU. Dāvis mentioned that sometimes they lack working hands, people who can help. They recently participated in the “Science night”, an open event, inviting everyone to explore and discover science and their work.

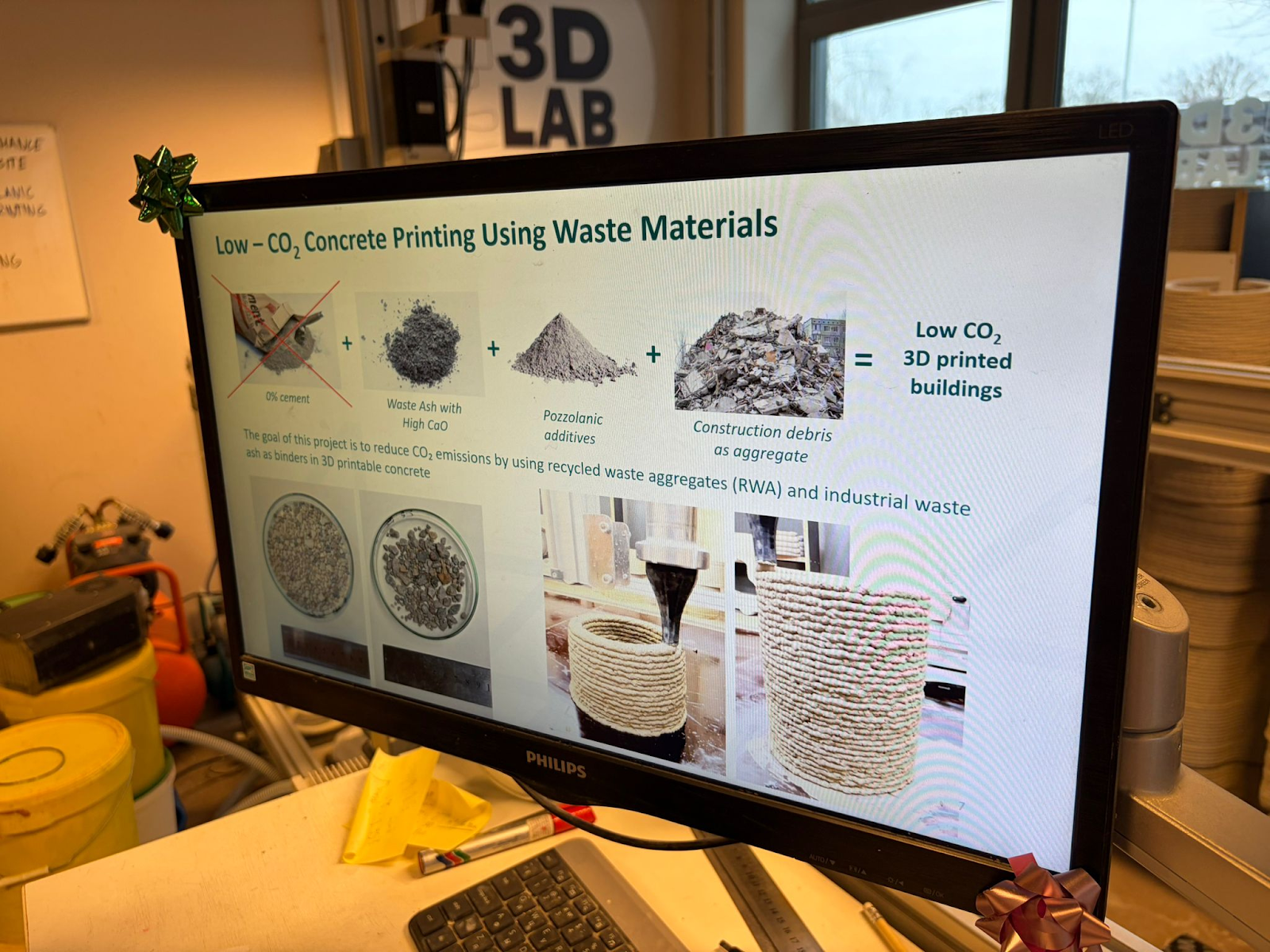

Looking ahead in the future, RTU 3D concrete printing lab continues to expand its research beyond conventional concrete. Current research, for example what Dāvis does, focuses on developing biodegradable and bio-based materials, as well as experimenting with alternative resources such as clay, opening new possibilities for sustainable construction, design, and art applications. By combining innovation, student participation, and community engagement through events like Science Night, the lab is not only shaping the future of additive manufacturing but also inspiring the next generation of engineers and researchers to build more responsible and creative technologies

Presentation:

Short:

Authors:

Petr Shvab, Ralfs Skavronskis, Maiks Vasilioglo, Edgars Smilgajs, Leonid Zhuravskii, Eduards Strokatovs