The €2 Million Science of Safety: Inside the RTU PPE Laboratory

When we get dressed each morning, we rarely stop to question the safety of the clothes we wear. But before any of those products reach users, they must pass a series of demanding tests—many of which take place inside the RTU Personal Protection Equipment Laboratory or PPE Lab for short. Here, garments are not judged by appearance or comfort, but by their ability to protect the human body in demanding and potentially dangerous environments. The laboratory’s work focuses on ensuring that personal protective equipment truly performs its function: reducing risk and preventing harm.

The RTU PPE Laboratory officially opened as a standalone facility in 2022, but its origins go back to 2020, when it was first established to test face masks.

Specialised equipment is used to test how well masks filter dust and particles.

At that time, the urgent global demand for reliable protective equipment highlighted the importance of accurate and standardised testing. As interest and investment in PPE research grew, the laboratory expanded both its space and its technological capabilities. Today, it operates as a fully equipped testing centre dedicated exclusively to evaluating protective clothing and materials.

Despite the complexity of the equipment and experiments, the laboratory is run by a relatively small team. Only five people work in the lab, each responsible for operating specialised machines, preparing tests, analysing results, and maintaining strict safety standards. Their work requires not only technical knowledge, but also patience and precision, as many procedures are long and must be carefully monitored from start to finish.

The laboratory contains a wide range of machines designed to simulate real-world conditions. A stretching machine is used to examine how materials behave when placed under mechanical stress, such as pulling, tension, and repeated movement. This is particularly important for protective clothing, which must remain intact even when the wearer is active. If a material tears or deforms too easily, it may fail to protect the person wearing it.

The stretching machine is used to test how protective materials respond to tension and mechanical stress.

Several other devices focus on surface durability and resistance. Peeling testers, known informally as “Marty” and the “pancake maker”, are used to analyse how layers of material separate and how coatings or protective films respond to force. These tests help determine whether protective surfaces will degrade over time or under harsh conditions. Another machine, nicknamed “Lietutiņš”, imitates rainfall and water exposure. This allows researchers to observe how fabrics react to prolonged contact with moisture, which is essential for equipment intended for outdoor work or wet industrial environments.

A peeling tester is used to analyse how material layers and coatings separate under pressure.

To ensure accurate and controlled experiments, the laboratory also relies on an Elga distilled water system. Distilled water is free from minerals and impurities, making it vital for tests where even small contaminants could influence the results. Although less eye-catching than the larger machines, this system plays a crucial supporting role in maintaining scientific reliability.

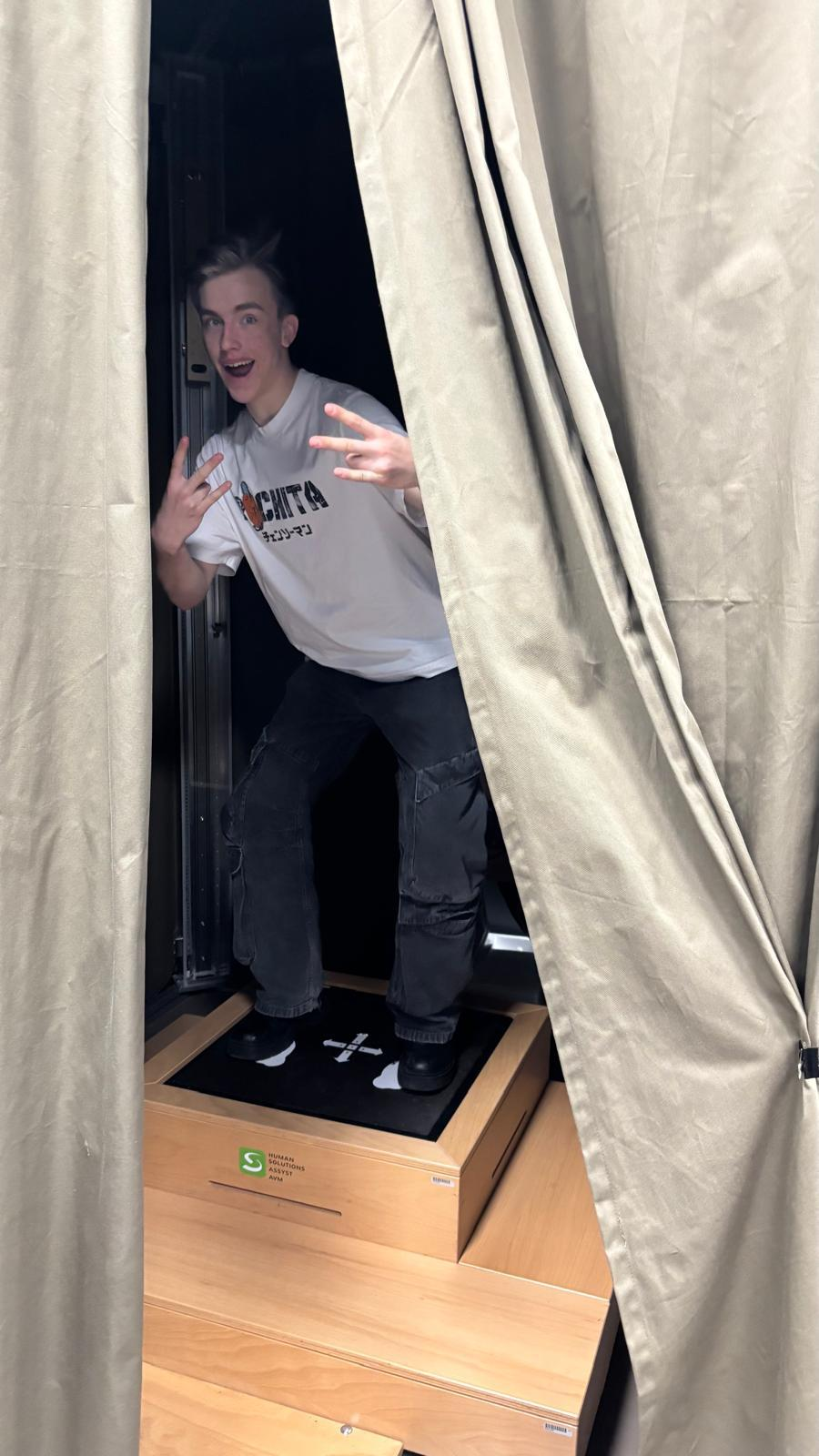

Another important piece of technology in the RTU PPE Laboratory is a full-body scanning system capable of creating extremely precise 3D models of people in a matter of seconds. This machine uses multiple sensors and cameras to capture the exact shape, proportions, and posture of the human body, producing a detailed digital model almost instantly. These scans are especially valuable in PPE research because protective clothing must fit correctly in order to function properly. Even small inaccuracies in size or shape can reduce protection, restrict movement, or cause discomfort. By using high-precision 3D models, researchers can analyse how equipment fits different body types, improve ergonomic design, and ensure that protective garments are both safe and practical for real users.

A body scanning system that uses infrared lasers to collect accurate measurements of the human body.

One of the most advanced and striking pieces of equipment in the laboratory is a sweating thermal manikin named “ANDI”. Costing around 500.000 Euros and only 14 produced in the whole world this life-sized doll can simulate human body heat, sweat production, and even movement. By using Andy, researchers can test how protective clothing performs under realistic conditions, including how well it manages heat and moisture. This is especially important for PPE, as poorly designed equipment can lead not only to discomfort, but also to overheating, dehydration, and reduced concentration. Andy is available in two versions, representing different body sizes, and costs around half a million euros, making it one of the most valuable devices in the facility.

Andi, a sweating thermal manikin, is used to test how protective clothing performs under realistic human conditions.

The scale of investment in the RTU PPE Laboratory reflects the importance of its work. The total cost of the laboratory is estimated to be around two million euros, covering specialised machinery, infrastructure, and safety systems. However, despite this large investment, the laboratory itself does not manufacture protective equipment. Its sole purpose is testing. By remaining focused on evaluation rather than production, the lab can provide objective and standardised results.

Many of the tests carried out in the laboratory are time-consuming. A single experiment can last around eight hours, requiring constant attention and precise control of conditions. Some procedures also involve significant hazards. Among the most dangerous are tests using sulphuric acid, which is highly corrosive and can cause severe injuries. These experiments highlight an interesting contrast: even in a laboratory dedicated to protective equipment, the researchers themselves must rely heavily on strict safety protocols and their own PPE.

In conclusion, the RTU PPE Laboratory represents an important link between everyday clothing and high-level scientific safety testing. While most people put on their clothes without a second thought, the work carried out in this laboratory ensures that protective garments can truly withstand the conditions they are designed for. Through advanced technology, specialised staff, and rigorous testing procedures, the RTU PPE Laboratory plays a vital role in making hazardous environments safer for those who work in them.

Kristaps Lucaus, Edvards Višs, Alekss Ucilodok, Alexander Semenov, Georgs Strogonovs, Gabriels Tomakins