Europe's biggest laboratory

Welcome to the RTU’s “Accredited Laboratory for Personal Protective Equipment” or PPE for short, the place where you can burn, tear, and test different materials with a variety of machines to find out how useful they are in real life situations. Materials tested there are used in the most extreme applications, such as firefighter and military clothing, by people all around the globe.

The laboratory was established in 2020 during the COVID-19 pandemic for the purpose of testing protection masks. As the pandemics passed by, the scope of the laboratory shifted. Laboratory's inventory has developed, and right now it has more testing equipment than any other laboratory in Europe. Companies from many different countries all around the world —ranging from our neighbors in Estonia to Brazil—cooperate with the laboratory. At present, the laboratory is working on an international “Horizon” project with companies like Adidas. Their goal is to create an innovative, bio-friendly textile material.

In the laboratory there are four main rooms. One of them serves as an office room and is also used for preparing samples for tests; the other three rooms are used for testing. These rooms are small and densely packed with various testing equipment.

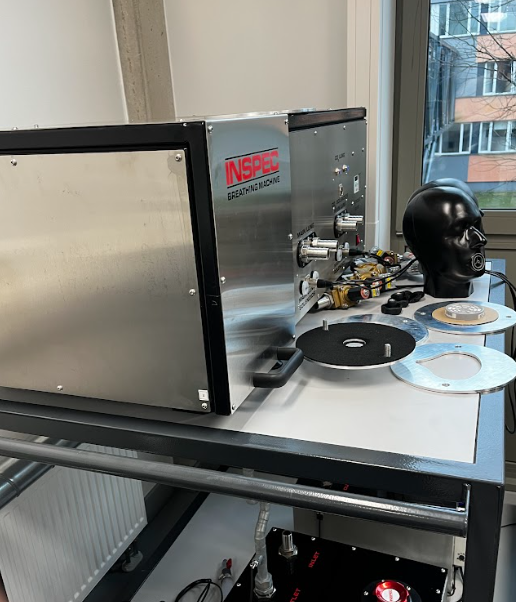

The first room requires special climate conditions, as the materials tested are sensitive to humidity and temperature. It is equipped with a range of devices, such as a washing machine, oven, pH tester, water resistance tester, tensile strength tester, and many others. It also houses a special device called the Sheffield head—which resembles a black head—that imitates breathing for testing respiratory equipment. In the center of this room, there is an isolated area for biological testing; this space is kept sterile, and people are allowed in only with permission.

The second room is where fun begins. While the first room is used mostly for small machines, the second room contains huge and more extreme machines. One of these is the “Rain Tester,” which evaluates clothing under rain conditions. Another machine, the so-called “Thermal Protective Performance Apparatus,” is used to test how different materials withstand heat. There are three types of heat tests—radiation heat, flame heat, and a combined test—with a different variation of the machine for each test.

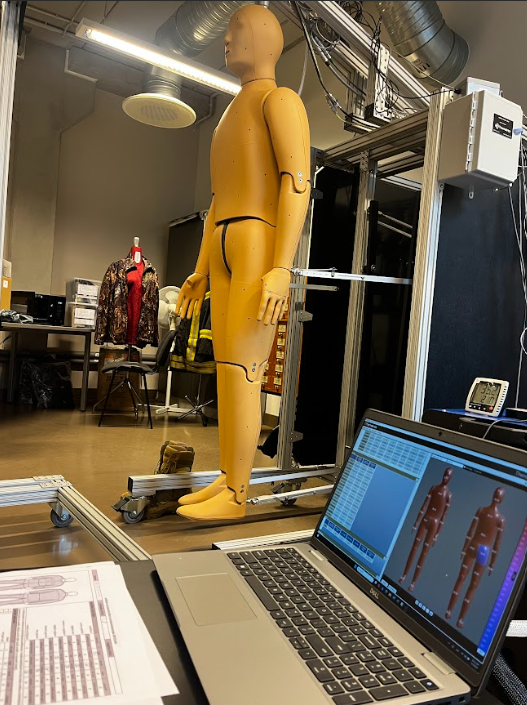

The third room has a single machine, “Andie,” a unique device that consists of a mannequin with many sensors, a mechanism that moves it, and a climate chamber. However, the laboratory does not have a climate chamber yet and is seeking financing to purchase one in the future. There are only 13 such machines in the world, and the complex without the chamber costs around 500000 dollars. Andie can imitate the movement and sweating of a real person and is connected to a nearby PC to collect data. The other similar machine is located at Dresden University. They also use small red figurines to keep the door open.

It is interesting that such a big and unique laboratory is operated by only four people and one research assistant, who is studying at RTU and is from Sri Lanka. The community is friendly and positive; people know each other and usually help and speak kindly to one another. The leader of the laboratory is Inga Dabolina, but she wasn’t present, so we spoke with two other researchers in the laboratory. One of them, Ph.D. Eva Lapkovska, answered our questions about her work at the laboratory.

She said that, in her opinion, the biggest achievement of the laboratory was its establishment as the largest facility of its kind. She also mentioned that the community is calm and sometimes even a little boring, since no one has time to do anything apart from testing and researching.

Overall, the RTU’s Accredited Laboratory for Personal Protective Equipment stands as a center of innovation in the field of protective gear testing. From its humble beginnings during a global crisis to its current status as the most equipment-rich facility in Europe, the laboratory not only pushes the boundaries of scientific testing but also unites the dedicated community of researchers. As it continues to collaborate on international projects and advance protective technologies, the lab is set to make significant contributions to safety standards around the world.

Article by Petr Shvab, Arsenijis Krasovskis, Nikolas Kaipovs and Aleksandrs Sergejevs.

Presentation: