Weld Done! – A journey forged in fire

Introduction

The term “weld” was first used in a late 14th century translation of the Bible. It originated from the Middle English word wæll, meaning ‘to heat’ or ‘bring to a boil’. This verb evolved to have a ‘d’ at the end as English shifted through Nordic and Germanic influences, ultimately forming the modern-day word all STEM majors know and love. Today, welding refers to uniting (metallic parts or plastics) by heating and allowing the parts to flow together or by hammering or compressing with or without previous heating.

It is a crucial process in the manufacture, construction, infrastructure development and repair of metallic structures. Today, it plays an indispensable role in our everyday life, as everything that facilitates our lives, from the houses we live in to the gadgets we use, are fabricated and repaired using this essential skill. The Welding Laboratory at RTU provides a valuable insight for students into this fundamental process, and a safe, controlled environment to learn by trying different types of welding. This research article documents our journey to this lab where we engaged in some hands-on welding experience, educated ourselves about safety measures to be taken while welding and the history and significance of this lab and its leaders.

The Start of the Journey

Didzis Avišāns, who has a PhD in Welding and is the main handler of the laboratory, led our group once we reached the Welding Lab.

Didzis commenced our journey with a quick look at the contents of the lab, which had 7 workstations, each with unique, state-of-the-art facilities to accommodate 3 types of Fusion Welding:

- Shielded Metal Arc Welding (SMAW) or Stick Welding

- Gas welding (Metal Inert Gas (MIG)/Metal Active Gas (MAG))

- Tungsten Inert Gas (TIG) Welding

Apart from these, the lab also has a new metal 3D printer and is waiting for laser welding technologies.

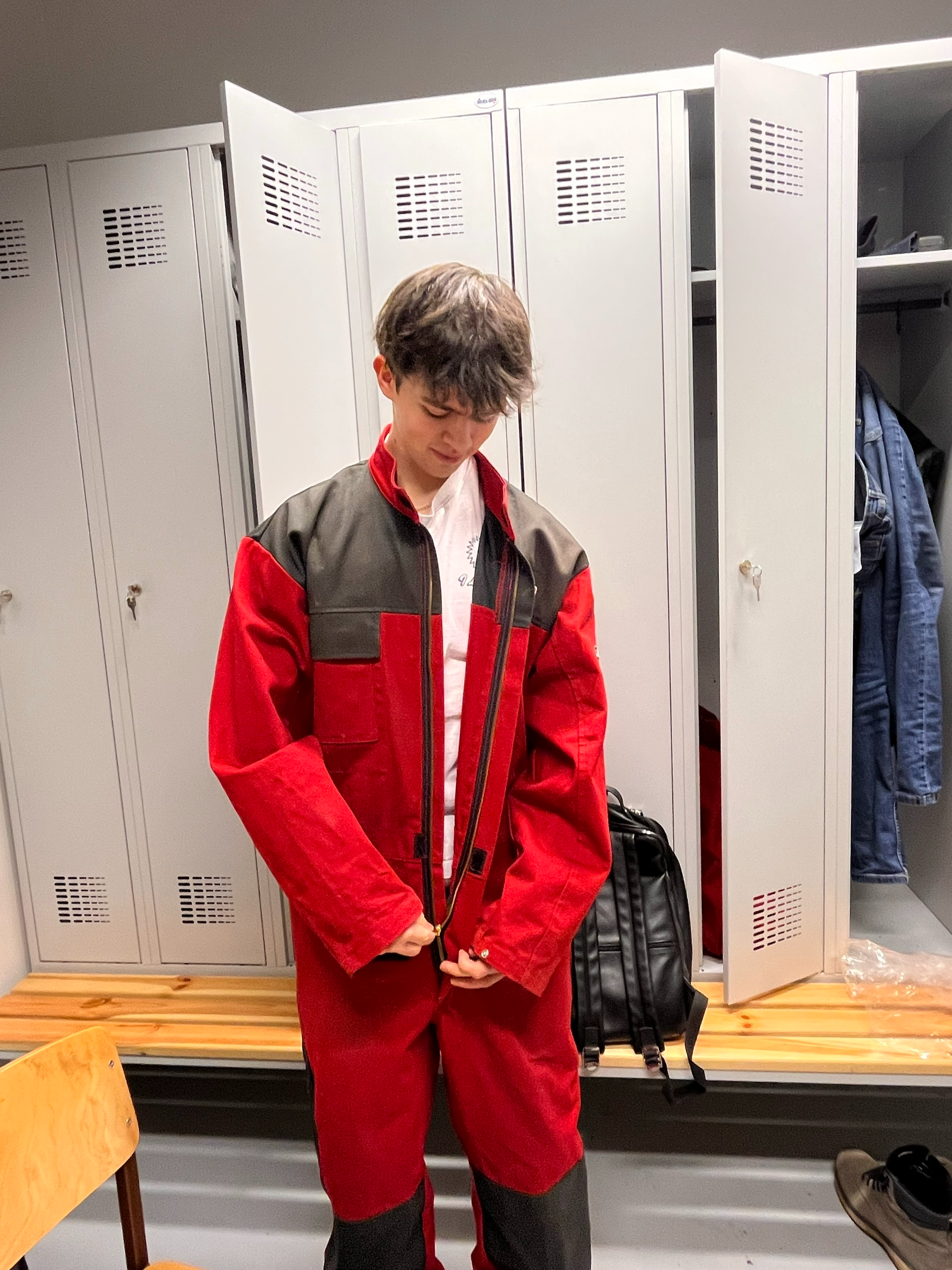

A lot of emphasis was put on safety measures and protective equipment. Since welding is done at extremely high temperatures and hence extremely dangerous for the skin and body, the following were an absolute necessity in the Lab, Didzis said:

- Heat-resistant gloves

- Special Welding Helmet

- Heat-resistant outerwear kit (termed Teletubby-wear by Didzis)

Each welding station also had a ventilator to prevent respiratory diseases caused by inhalation of toxic fumes and gases released when welding.

The lab provided each of us with these PPE kits that included all of the above three. RTU Welding Lab’s strict adherence to safety rules shows its dedication to providing students with a no-risk, educational environment.

Stick Welding (SMAW)

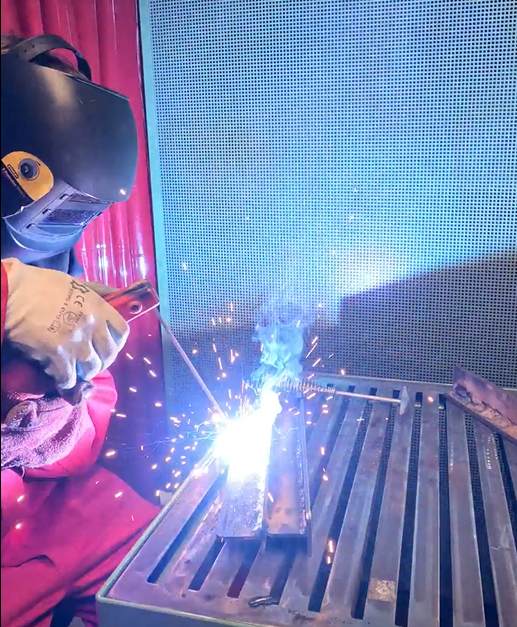

Equipped with our personal PPE kits, we proceeded to have hands-on experience with the fundamental type of Manual Welding – Stick Welding.

Stick Welding involves using a flux-coated electrode to create an electric arc between the electrode and the base metal, resulting in a weld pool that solidifies to form a joint.

Under the careful guidance of our mentor, we practised the basics of Stick Welding:

- Striking the spark

- Holding the arc

- Maintaining the electrode angle

- Maintaining proper travelling speed

- Cleaning the welded joint

Each of us practised multiple times under Didzis’ close guidance, who taught us the nuances of each technique. He helped us improve our hand-eye coordination, precision, observation skills and dexterity to produce quality welds.

The History, the Present and the Future

After demonstrating the welding processes in the laboratory, Didzis shared insights about the lab itself.

The lab opened about 10 years ago as part of RTU, though it was initially under a different institute. In 2020, it was handed over to Didzis Avišāns, who was pursuing his PhD at RTU at the time.

Currently, the lab serves as an open space for students of all levels—from complete beginners to seasoned professionals—to experiment, learn, and refine their welding skills. Didzis maintains a friendly, welcoming atmosphere to encourage more students to participate. However, he notes that once students are in the lab, they become laser-focused, with many requesting additional hours to work on personal projects. The lab also hosts a significant number of international students, with a 3-to-7 ratio compared to the slight majority of local students.

While this educational focus remains central to the lab’s mission, Didzis envisions expanding its role. He aims to increase the lab's global reach through collaborations with manufacturing companies on projects in various industries, from aerospace to technology. The RTU Welding Lab has already partnered with ESAB, a world leader in welding and cutting equipment, and with their support, the lab has launched an Aluminium Welding Project.

A special area of interest for Didzis's vision for the future is the integration of the 'Co-bot'—an industrial welding robot designed to collaborate with humans. This innovation aims to improve functionality and efficiency in welding tasks.

Factoids

In addition to its core function as a training space, the RTU Welding Lab is also home to a variety of quirky projects and oddities. We were fortunate enough to get a glimpse of some of them.

At the front of the lab, we found several independent welding projects on display, showcasing the students' dedication to both the art of welding and their university.

We also came across an old point (spot) welder from the 1970s, which Didzis affectionately calls "the Granny of Robot Welders."

Additionally, Didzis shared the tale of a pair of new shoes with a rather unfortunate history. Having once attempted to weld while wearing them, Didzis inadvertently set them on fire. The shoes have since become an urban legend in the lab, serving as a cautionary reminder to all: never wear new shoes when working in the Welding Lab.

Conclusion

To conclude, our exploration of the welding laboratory offered valuable insights into the practical aspects of welding, the critical importance of safety measures, and the facility's historical evolution. Engaging directly with welding processes and understanding the role of PPE has deepened our appreciation for the skill and precision required in this field. Moreover, the RTU Welding Laboratory's exciting future has highlighted its pivotal role in the rapidly advancing fields of welding education and research. This experience has transformed our understanding of welding, shifting it from a technical skill to an art form with immense industrial significance.

Presentation:

-Ralfs Skavronskis, Alberts Čupriks, Bheeni Vig